Transuranic (TRU) waste removal

Preparation of the RH-72B Shipping Cask prior to its departure. The material in the cask is being shipped to the Waste Isolation Pilot Plant (WIPP) in Carlsbad, NM for ultimate disposal.

Transuranic (TRU) waste removal

The shipping truck leaves Argonne, containing waste secured during ARRA funded clean-up projects. Some of this material is leaving the site six months ahead of schedule.

ARRA-funded work at Building 331

Workers load the RLC into the shipping cask. This is a heavily shielded and very secure shipping cask that will ensure the RH TRU waste containers are safely

ARRA-funded work at Building 331

Workers load RH TRU drums into an RLC container which will be transported to the Waste Isolation Pilot Plant (WIPP) for disposal. The Next-Phase Transuranic Waste Project is squarely focused on reducing the quantity of transuranic waste currently housed at Argonne. Removal of this material supports Argonne’s overall goal of reducing its nuclear footprint. The project accelerates work that has already begun by providing additional resources to drive projects across the site. Acceleration of these tasks will reduce future surveillance and maintenance costs associated with these facilities and support the goal of future decommissioning of these facilities. Reducing the life-cycle costs of these areas will allow for more effective delivery of resources to support research and development work at the laboratory.

ARRA-funded work at Building 331

Workers begin the loading process for moving RH TRU drums from behind the shielded wall in the 331 Yard, to the RLC containers, in preparation for shipment to the Waste Isolation Pilot Plant for disposal. The Next-Phase Transuranic Waste Project is squarely focused on reducing the quantity of transuranic waste currently housed at Argonne. Removal of this material supports Argonne’s overall goal of reducing its nuclear footprint. The project accelerates work that has already begun by providing additional resources to drive projects across the site. Acceleration of these tasks will reduce future surveillance and maintenance costs associated with these facilities and support the goal of future decommissioning of these facilities. Reducing the life-cycle costs of these areas will allow for more effective delivery of resources to support research and development work at the laboratory.

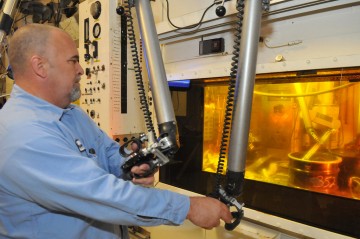

ARRA-funded work at Alpha Gamma Hot Cell Facility

Hot Cell Techs working in the AGHCF. Remote-handled transuranic waste (RH-TRU) is packaged and certified in the hot cell. The waste will be transported to the Waste Isolation Pilot Plant (WIPP) for disposal. The Next-Phase Transuranic Waste Project is squarely focused on reducing the quantity of transuranic waste currently housed at Argonne. Removal of this material supports Argonne’s overall goal of reducing its nuclear footprint. The project accelerates work that has already begun by providing additional resources to drive projects across the site. Acceleration of these tasks will reduce future surveillance and maintenance costs associated with these facilities and support the goal of future decommissioning of these facilities. Reducing the life-cycle costs of these areas will allow for more effective delivery of resources to support research and development work at the laboratory.

ARRA-funded work at Alpha Gamma Hot Cell Facility

Hot Cell Techs working in the AGHCF. Remote-handled transuranic waste (RH-TRU) is packaged and certified in the hot cell. The waste will be transported to the Waste Isolation Pilot Plant (WIPP) for disposal. The Next-Phase Transuranic Waste Project is squarely focused on reducing the quantity of transuranic waste currently housed at Argonne. Removal of this material supports Argonne’s overall goal of reducing its nuclear footprint. The project accelerates work that has already begun by providing additional resources to drive projects across the site. Acceleration of these tasks will reduce future surveillance and maintenance costs associated with these facilities and support the goal of future decommissioning of these facilities. Reducing the life-cycle costs of these areas will allow for more effective delivery of resources to support research and development work at the laboratory.

UREX+ Nuclear waste recycling

The UREX+ process can minimize waste from today's commercial reactors. Chemical engineer Monica Regalbuto and technician Mark Clark work on the UREX+ process in the hot cell. A series of centrifugal contactors can be seen in the hot cell.