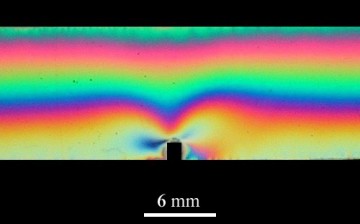

Strain-induced birefringence in a notched polycarbonate bar

Strain-induced birefringence in a notched polycarbonate bar.

The colours in the image are the result of birefringence and relate to the strain-induced alignment of the polycarbonate molecules. Because the specimen is below the glass transition temperature of PC (145 deg C), the material will relax when the stress is removed and there will be no residual alignment. The colours reveal the pattern of stress concentration around the notch.

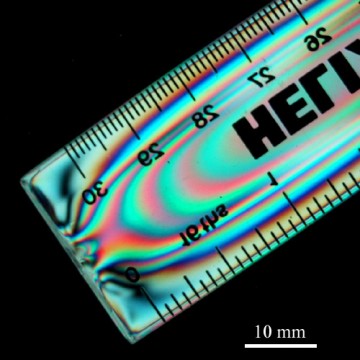

Injection-moulded polystyrene ruler

Injection-moulded polystyrene ruler.

The colours in the image are the result of birefringence and relate to the residual strain in the polystyrene. The pattern of strain is indicative of the flow of material during the injection process and it highlights the injection point (known as a 'gate') at the end of the ruler; the molecular alignment is greatest near this point. Towards the edges of the ruler and along its length, the material becomes more relaxed and as the molecular alignment falls, the retardation of light is less. If heated above the glass transition temperature of polystyrene (about 100 deg C), the material will tend to relax, particularly along the centreline, near the gate. This will result in a wrinkled form.

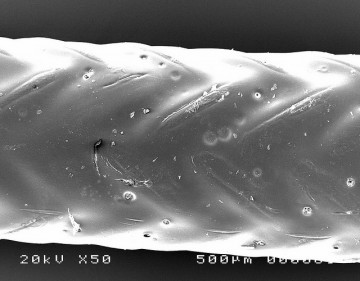

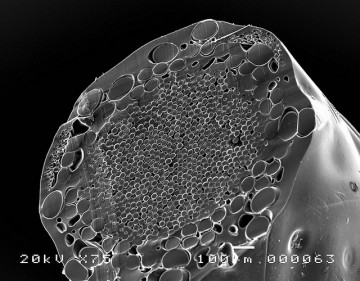

Structure of a tennis string

SEM micrograph of a sectioned tennis string. Courtesy of Prof Claire Davis and Elizabeth Chandler, School of Metallurgy and Materials, University of Birmingham.

Structure of a tennis string (2)

Structure of a tennis string.

SEM micrograph of a sectioned tennis string. Courtesy of Prof Claire Davis and Elizabeth Chandler, School of Metallurgy and Materials, University of Birmingham.

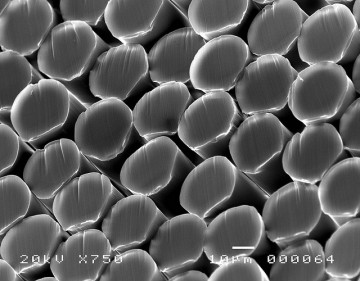

Structure of a tennis string (3)

Structure of a tennis string.

SEM micrograph of a sectioned tennis string. Courtesy of Prof Claire Davis and Elizabeth Chandler, School of Metallurgy and Materials, University of Birmingham.

Wood and CFRP tennis rackets

Wood and CFRP tennis rackets.

Photo of tennis rackets made of wood and carbon fibre reinforced plastics (CFRP) showing increase in racket head for the CFRP. Courtesy of Prof Claire Davis, School of Metallurgy and Materials, University of Birmingham.

Bild: CORE-Materials